Originally Posted by Crash Dummy

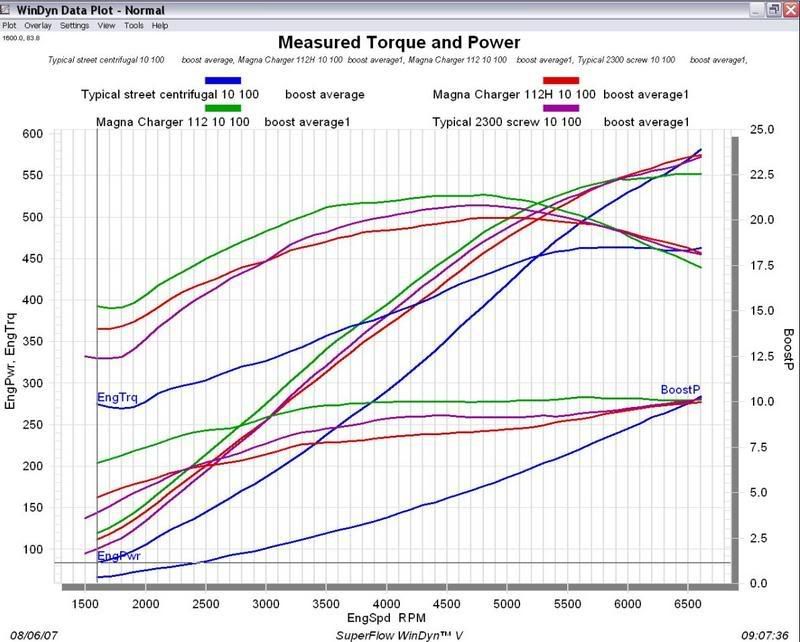

OK I did a blower test on our Superflow engine dyno using a stock 5.3 truck engine with a GT2-3 cam, 90mm T body, de-screened MAF and 1 7/8 long tubes with no cats and I used the same manifold, same water inter cooler, same everything only changing just the supercharger for each test. Each test was pulley matched to produce 10lbs of boost at 6500 rpm and all test were run on VP103 ( 100 oct) gas, 12.0 AFR, and the timing locked at 24 degrees the only difference is just the supercharger and all test were done on the same day. As you can see our little 112 as we all know starts running out of airflow at around 550-600 HP and our 112H does not run out for a other 50-75 HP. I wish I had done this test and matched them all at 6lbs at 4000 RPM because that would have shown both ends of the test and produced totally different results but if you truly have a 10 lb kit this is what you are going to see. I also did this test at 7 lbs on pump gas and had the same results except the 112 did not run out of air. Anyway here is the results for you to look over, like I said this was more of a 6500 rpm test to prove that a given amount of boost at a given rpm from any FI power adder the results will be very similar.

![Image]()

OK I did a blower test on our Superflow engine dyno using a stock 5.3 truck engine with a GT2-3 cam, 90mm T body, de-screened MAF and 1 7/8 long tubes with no cats and I used the same manifold, same water inter cooler, same everything only changing just the supercharger for each test. Each test was pulley matched to produce 10lbs of boost at 6500 rpm and all test were run on VP103 ( 100 oct) gas, 12.0 AFR, and the timing locked at 24 degrees the only difference is just the supercharger and all test were done on the same day. As you can see our little 112 as we all know starts running out of airflow at around 550-600 HP and our 112H does not run out for a other 50-75 HP. I wish I had done this test and matched them all at 6lbs at 4000 RPM because that would have shown both ends of the test and produced totally different results but if you truly have a 10 lb kit this is what you are going to see. I also did this test at 7 lbs on pump gas and had the same results except the 112 did not run out of air. Anyway here is the results for you to look over, like I said this was more of a 6500 rpm test to prove that a given amount of boost at a given rpm from any FI power adder the results will be very similar.